Epoxy Floors – Pros And Cons

Epoxy floors are concrete floors that are painted with an epoxy coating. Also known as polymer seamless floors, they typically have a clear or colored finish, and often are a replacement for concrete sealants. Epoxy floors are used in industrial settings as well as in garages, pool decks, work areas, and laundry rooms in private homes, but have recently become an option for decorating other indoor living spaces.

These types of floors are durable and are slip, stain and dust-resistant. Epoxy floors reflect natural or artificial light and are easy to clean. They are also resistant to chemical spills. Provided surfaces are prepared correctly, epoxy floor coatings are extremely durable. They come in several colors including clear, silver-gray, and slate-gray and may also be tinted to a specific color using a white or dark base color.

Epoxy floors -various colors and patterns

Epoxy floor coatings can be used for both exterior and interior applications, but should not be used on vertical surfaces, wood, or metal surfaces, or where there is standing water at any time of the year. Likewise if there are high levels of moisture below grade under a garage or basement slab, epoxy floor coatings should not be used.

The most important and direct benefit of the use of epoxy floors is the fact that they require very low cost for cleaning, maintenance and sanitation, thus allowing an owner to make significant financial savings. Using epoxy floors also generates indirect benefits, such as eliminating the risks of contamination of devices, instruments, utensils and food and, equally important, epoxy floors are absolutely harmless to the environment after the end of the chemical process of polymerization.

Apart from their decorative role, epoxy floors also make a fine hydro-insulator, hence their primary use in kitchens, bathrooms, basements and cellars. It also a warmer floor than classic tile, concrete or marble floors. As concerns cons, we remind the tendency to scratch easily and a low resistance to impact.

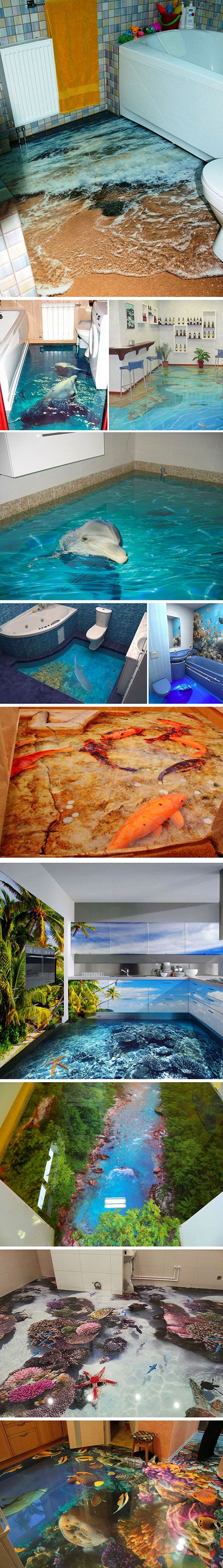

Epoxy floors – fascinating 3D models

As concerns the types of floors, thin mil floor coatings are used in garages and are similar to a concrete sealer. Self-leveling polymer floor coatings are used for concrete floors that have chipped or flaked and need resurfacing. They are perfect for high-traffic areas but should not be used where there are high levels of moisture below grade.

Quartz broadcast polymer floor systems are made from a mixture of tiny pieces of quartz and polymer. The quartz adds color to the floor. Troweled polymer floor systems are made from a mixture of silicon aggregate and polymer and are used for industrial applications only.

Sources: Homedoctor.net, Houzz.com, Pinterest.com, Ems-floor.ro